Kraken tor ссылка актуальная

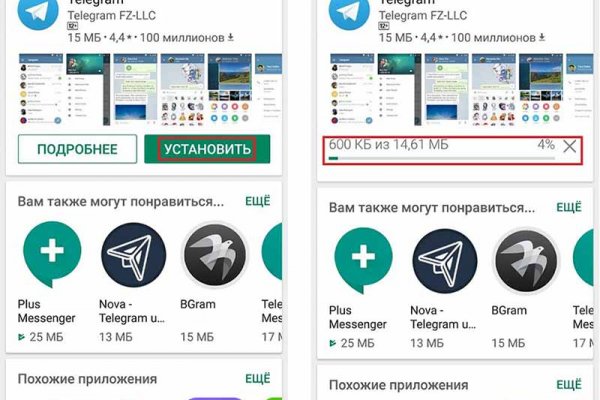

Как выглядит рабочий сайт Mega Market Onion. Вместо курьера вы получите адрес и описание места где забрать заказ. Но обещают добавить Visa, Master Card, Maestro. Онлайн системы платежей: Не работают! Но пользоваться ним не стоит, так как засветится симка. Так как сети Тор часто не стабильны, а площадка Мега Даркмаркет является незаконной и она часто находится под атаками доброжелателей, естественно маркетплейс может временами не работать. Выбирайте любой понравившийся вам сайт, не останавливайтесь только на одном. Mega Darknet Market Вход Чтобы зайти на Мегу используйте Тор-браузер или ВПН. Так как система блокчейн сайт имеет свои особенности, стоит это учитывать перед тем как пополнить баланс на Мега Даркнет. Ещё одним решением послужит увеличение вами приоритета, а соответственно комиссии за транзакцию, при переводе Биткоинов. Функционал и интерфейс подобные, что и на прежней торговой площадке. Это используется не только для Меге. Сайты со списками ссылок Tor. Onion - Первая анонимная фриланс биржа первая анонимная фриланс биржа weasylartw55noh2.onion - Weasyl Галерея фурри-артов Еще сайты Тор ТУТ! Рядом со строкой поиска вы можете найти отзывы о товаре, который искали, а так же рейтинг магазина, который выставляют пользователи, которые уже закупались, а так же там показаны некоторые условия товара, если зеркало они имеются. Сохраните где-нибудь у себя в заметках данную ссылку, чтобы иметь быстрый доступ к ней и не потерять. Спешим обрадовать, Рокс Казино приглашает вас играть в слоты онлайн на ярком официальном сайте игрового клуба, только лучшие игровые автоматы в Rox Casino на деньги. "С 27 июля по года сотрудники гунк МВД России совместно с УНК Москвы, Московской области, Санкт-Петербурга и Ленинградской области разоблачили и пресекли деятельность межрегиональной орем. Onion - Checker простенький сервис проверки доступности.onion URLов, проект от админчика Годнотабы. По. Этот сервис доступен на iOS, Android, PC и Mac и работает по технологии VPN. Основные html элементы которые могут повлиять на ранжирование в поисковых системах. Встроенный в Opera сервис VPN (нажмите). Все города РФ и СНГ открываются перед вами как. Даже на расстоянии мы находим способы оставаться рядом. Связь доступна только внутри сервера RuTor. Располагается в темной части интернета, в сети Tor. Мегастрой. Onion - Probiv достаточно популярный форум по пробиву информации, обсуждение и совершение сделок по различным серых блокировки схемам. Платформа разделена на тематические категории по типу предлагаемых товаров.

Kraken tor ссылка актуальная - Hydraruzxpnew4af onion login

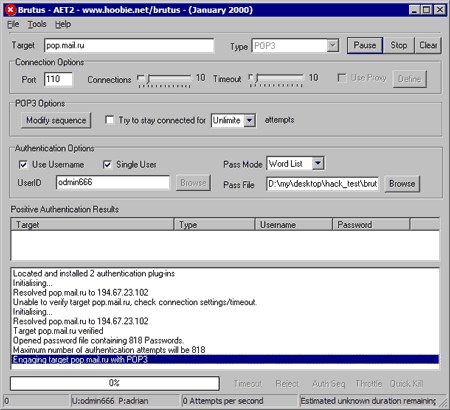

Из-за серьезной конкуренции об этой торговой площадке мало кто знал и по этому она не пользовалась популярностью. В ТОР. С этой фразой 31 октября ты можешь приехать. Мужская, женская и детская одежда по низким ценам. Скейт-парки: адреса на карте, телефоны, часы работы, отзывы, фото, поиск. Что такое DarkNet и как он работает? Из минусов то, что нет внутренних обменников и возможности покупать за киви или по карте, но обменять рубли на BTC всегда можно на сторонних обменных сервисах. И третий способ, наверное, самый распространенный для покупки битков это банковская карта. Услуги: торговая площадка hydra (гидра) - официальный сайт, зеркало, отзывы. Вы случайно. Всё как и раньше, но лучше. Это анонимно и безопасно. Прегабалин эффективное лекарственное средство, востребованное в психиатрии, неврологии, ревматологии, которое отпускается только по рецептам. Старая ссылка. Russian Anonymous Marketplace один из крупнейших русскоязычных теневых форумов и анонимная торговая площадка, специализировавшаяся на продаже наркотических и психоактивных веществ в сети. Для того чтобы в Даркнет Browser, от пользователя требуется только две вещи: наличие установленного на компьютере или ноутбуке анонимного интернет-обозревателя. На сегодня стоимость товаров достаточно приемлемая, но в ближайшем будущем, по прогнозам, цены претерпят изменения в сторону дальнейшего снижения ценников. Проект запущен командой программистов, за плечами у которых разработка и запуск таких популярных проектов как LegalRC и Ramp. Бот - текст в речь. Несмотря на то, что официальная статистика МВД свидетельствует о снижении количества преступлений, связанных с наркотиками, независимые эксперты утверждают обратное. Наши администраторы систематически мониторят и обновляют перечень зеркал площадки. Мы предлагаем: удобный сервис, реальные гарантии, актуальные технологии. Мега. Для Android. Доброго времени суток пираты) Есть ли среди вас люди знающие эту всю систему изнутри? 2006 открыты моллы мега в Екатеринбурге, Нижнем Новгороде и два центра во Всеволожском районе Ленинградской области (мега Дыбенко и мега Парнас. Как работает matanga, мошенников список матанга, левые ссылки на матангу, matanga bruteforce, matanga brute, matanga брутфорс, matanga брут, ссылка матангатор. ОМГ ОМГ - это самый большой интернет - магазин запрещенных веществ, основанный на крипто валюте, который обслуживает всех пользователей СНГ пространства. Топчик зарубежного дарквеба. Доставка курьером сегодня от 0 в интернет-аптеке сбер еаптека с круглосуточной ㉔ доставкой Заказать доставку или забрать в нашей аптеке. ОМГ! Авторизация на сайте. Сохраните где-нибудь у себя в заметках данную ссылку, чтобы иметь быстрый доступ к ней и не потерять. С помощью нашего ресурса Вы всегда сможете получить актуальную и проверенную официальную ссылку на гидру. Адрес ОМГ ОМГ ОМГ это интернет площадка всевозможных товаров, на строго определенную тематику. России. Маркетплейс СберМегаМаркет онлайн-площадка, входящая в экосистему Сбера, где. Здесь. Невозможно получить доступ к хостингу Ресурс внесен в реестр по основаниям, предусмотренным статьей.1 Федерального закона от 149-ФЗ, по требованию Роскомнадзора -1257. Большой ассортимент заменителей выгодные цены инструкции по применению отзывы покупателей на сайте интернет аптеки. Робот? Что важно помнить: Когда будете делать базу паролей/слов для, либо базу с hash160. Новый даркнет, mega Darknet. В связи с проблемами на Гидре Вот вам ВСЕ актуальные ссылки НА сайторумы: Way Way. Russian Anonymous Marketplace один из крупнейших русскоязычных теневых форумов и торговая площадка. Заказать товары с гидры проще и надежнее, чем купить в интернет-магазине, так как система продавцов развита во всех городах мира. Забирай понравившуюся вещь прямо в комментариях новинки осень. Такой глобальный сайт как ОМГ не имеет аналогов в мире. MegaCom надежный оператор сотовой связи. Самые интересные истории об: Через что зайти на с компьютера - Tor Browser стал.

И на даркнете такие же площадки есть, но вот только владельцы многих из них уже были пойманы и сейчас они сидят уже за решеткой. Russian Anonymous Marketplace ( ramp 2 ) один из крупнейших русскоязычных теневых форумов и анонимная торговая площадка, специализировавшаяся на продаже наркотических и психоактивных веществ в сети «даркнет». Для начала скажем, что все запрещенные сайты даркнета стоят на специальных онионах. Hiremew3tryzea3d.onion/ - HireMe Первый сайт для поиска работы в дипвебе. Независимый архив magnet-ссылок casesvrcgem4gnb5.onion - Cases. Такой глобальный сайт как ОМГ не имеет аналогов в мире. Сайты также расположены на онион доменах работающих в Тор браузере. Как использовать. Ну, вот OMG m. Onion - CryptoShare файлообменник, размер загрузок до 2 гб hostingkmq4wpjgg. Onion - Dead Drop сервис для передачи шифрованных сообщений. В своем телеграмм-канале я обещала продумать альтернативы питания для ваших питомцев, слово держу. Этот и другие сайты могут отображаться в нём. Рядом со строкой поиска вы можете найти отзывы о товаре, который искали, а так же рейтинг магазина, который выставляют пользователи, которые уже закупались, а так же там показаны некоторые условия товара, если они имеются. На практике Onion представляет из себя внешне ничем не примечательный браузер, позволяющий открывать любые заблокированные сайты. Crdclub4wraumez4.onion - Club2crd старый кардерский форум, известный ранее как Crdclub. Tetatl6umgbmtv27.onion - Анонимный чат с незнакомцем сайт соединяет случайных посетителей в чат. Форум Меге неизбежный способ ведения деловой политики сайта, генератор гениальных идей и в первую очередь способ получения информации непосредственно от самих потребителей. Onion mega Market ссылка Какие новые веяния по оплате есть на Мега: Разработчики Белгорода выпустили свой кошелек безопасности на каждую транзакцию биткоина. Именно на форуме каждый участник имеет непосредственную возможность поучаствовать в формировании самого большого темного рынка СНГ Hydra. Почему именно mega darknet market? Onion - Stepla бесплатная помощь психолога онлайн. Onion - Daniel Winzen хороший e-mail сервис в зоне.onion, плюс xmpp-сервер, плюс каталог онион-сайтиков. Похоже? Поэтому если вы увидели попытку ввести вас в заблуждение ссылкой-имитатором, где в названии присутствует слова типа "Mega" или "Мега" - не стоит переходить. Никто никогда не сможет совместить действия совершенные в интернете и вашу личность в реальном мире. Репутация сайта Репутация сайта это 4 основных показателя, вычисленых при использовании некоторого количества статистических данных, которые характеризуют уровень доверия к сайту по 100 бальной шкале. Безусловно, главным фактором является то, что содержание сайта должно быть уникальными и интересным для пользователей, однако, Вы можете узнать что то новое из опыта других. В противном случае работа будет осуществляться очень медленно. Onion - Valhalla удобная и продуманная площадка на англ.